COMPANY PROFILE

Derui Sanitaryware (China) International Industry Co. Ltd. was established in 2003, we are a professional High-quality Sanitary ware manufacturer and salen.Professional OEM/ODM, large-scale mass production.

We are always insisted on "quality products, first- class service, good reputation" as the company's business philosophy since our company established in these more than 10 years. "Fordwell" sanitary ware is one of the company's well-known brands. Its products have fashionable design and high standard craftsmanship, products mainly including All kind of Toilets, All kind of basins. Squatting pans, Bidet,Water tank, Urinal etc. We sell Sanitary ware base on 900,000 sets every years and the sell quantity are increased year by year.

Derui has independent import and export rights. Its main business is OEM production for sanitary ware importers and wholesalers in all regions of the world, with high quality, high standards and high efficiency. At the same time, we can provide technical support and Supporting production equipment.At present. Our products through network sale to our domestic provinces and exported to many countries and regions in the world, such as Africa, Southeast Asia.Europe, and the Middle East.

Our company has a group of high-quality, experienced technical management personnel and excellent sales staff. We has fully passed the IS09001: 2000 international quality control system. The introduction of a full set of foreign advanced production equipment. The use of fully automatic computer control for products from design to selection of raw materiaIs.Through unique craftsmanship and first-class production technology, our products have always dominated the sanitary ware in terms of design, quality, and style.

Derui company is committed to building the Bossfo rd, Fo rd we 11 bra nd, adheres to the business and through strengthening service awareness and implementing customer-oriented thinking, making high-quality products and first-class services become the main characteristics of Derui company. Create a more comfortable living space for consumers. Our slogan is to create high-quality sanitary ware and enjoy a happy life. We believe that through every cooperation, we will become a sincere, friendly, trustful and happy business partner

CERAMIC FEATURES

1280 degree high temperature firing makes the product truly porcelain and the advantages of well enduring high temperature , wear-resistant and water non-absorbent.Imported special glaze formula, the glaze is smooth and delicate, the surface of product is wear-resistant, well stain resistance, and easy to clean.

Long-term use always as new.

The introduction of Ceramic product :

1) Raw materials of ceramic production

They are divided into clay and glaze. The raw materials are basically the same, but the ratio of raw materials are different.

The main materials : feldspar, quartz, zinc oxide, zirconium oxide, aluminum powder, magnesium oxide, pigments. K2O, SiO2, ZnO, ZrO2, Al2O3, MgO

Clay: A kind of clay used in the production of pottery and porcelain.

Porcelain: A finished product that is completely into porcelain during high-temperature firing.

Ceramic: A finished product that has not been full into porcelain during high-temperature firing.

The difference between porcelain and ceramic are raw material formula, product water absorption situation, firing temperature.

Slurry: The raw material used for forming and grouting.

Glaze: raw material used for spraying glaze on semi-finished products.

Production process: ball milling, sieving, iron removal, pool storage.

Ball milling and sieving must meet the national standard of 325 objective.

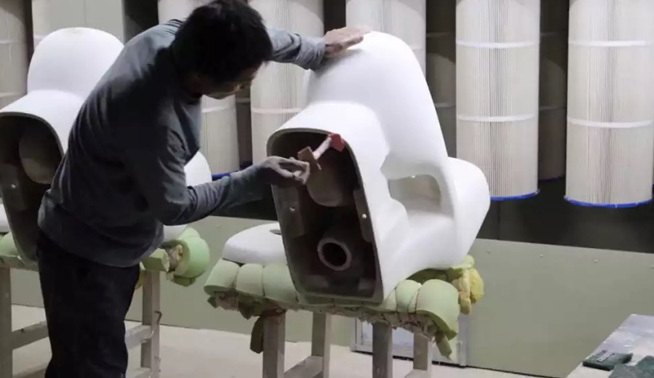

2) Mould

Gypsum mold for molding and grouting.

Material: gypsum powder

Features: fast water absorption, short setting time, easy repair and low price.

Times of Grouting: 80-120 times.

Production process: 3D drawing design, artificial sculpture original model , original model made of resin. The copy mold produced by the original mold is used for forming and grouting.

3) Forming grouting

Use the clay to form a semi-finished embryo in a plaster mold.

each molded product are combined at least two modular models

Forming method: single-sided adsorb clay. Double-sided adsorb clay.

Production process: grouting, outflow clay, demoulding, splicing ,drilling and clay body repair.

4) Spray glaze

Spray the glaze evenly on the embryo body.

Glaze spraying method; robot spraying glaze, manual glazing.

5) Firing

The product finished in glazing embryo body product formed after a fix time being heated at a high temperature in the kiln.

Firing shrinkage: not more than 1.15

Firing time: 13 hours - 15 hours.

Firing temperature: 1210。C- 1280。C.

Firing process: preheating zone, firing zone, cooling zone.

Kiln types: shuttle kiln, tunnel kiln.

6) Inspection

①Product’s research department:

Clay : close reading, specific gravity (moisture content), shrinkage, strength, bending resistance, flow, thixotropy.

Glaze: flow, thixotropy, density, specific gravity, color difference, high temperature flow, drying time, embryo glaze adaptability (in order to control thermal stability).

Chromatic aberration: The production glaze’s color are compared with the American KOHLER standard color palette, which using imported colorimeter.

Color: visual inspection.

Testing of raw materials used: clay, glaze, gypsum.

Monitoring kiln temperature: temperature measuring cone.

Re-fired filler and secondary glaze preparation. Product’s water absorption and thermal stability.

②Quality inspection department:

The checking for new product , including size, flushing function, packaging, etc.

Product improvement qualification test.

Comprehensive product spot check and testing.

Sampling inspection of graded products (sampling inspection before warehousing).

③Terms and definitions

1.The surface bulging part of a glaze bubble whose size does not exceed 1 mm.

2.Size of Small blister surface bulging part is between (1-3) mm .

3.Size of Big blister surface bulging part is exceeds 3mm.

4.Dia.of pinholes on the glazed surface that are not more than 1mm.

5.Size of pit on the glaze surface are more than 1mm .

6.heterochromatic spots whose speck size does not exceed 1mm. Unless the quantity is sufficient to cause discoloration.

The size of Spots less than 0.3mm dense enough to cause discoloration can be ignored.

7.Small mottling spot size is between (1-3) mm heterochromatic spot.

8.Big spot size is between (3-6) mm heterochromatic spot.

QUICK NAVIGATION

Honor

Let more people enjoy a better life

Plant

Integrity, innovation, simplicity, cooperation and effectiveness

Workshop

The goal is to satisfy customers; Customer oriented

Derui Sanitary Ware(China) International Industry Co.,Ltd.

GUANGZHOU DERUI IMPORT& EXPORT CO.,LTD

Guangzhou Office: Yuexiu District,GuangZhou city ,Guangdong Province, China

Add No.1 Factory : Houlong Industrial Zone, Fengtang Town, Chaozhou City, Guangdong Province, China

Add No.2 Factory : Fengyang Industrial Zone, Guxiang Town, Chaozhou City, Guangdong Province, China

Tel:0086-768-6190910

Fax:0086-768-5322069

MP:+8613318932365

Whatsapp/WeChat:+86-13318932365

Enterprise President : Addison Chiu

Web: www.derui-china.com

https://derui-china.en.alibaba.com

E-mail :CEO@derui-china.com / info@derui-china .com

export@derui-china.com / sales@derui-china.com

market@derui-china.com / service@derui-china.com

Copyright (c) Derui Sanitaryware (China) International Industry Co. Ltd. All Rights Reserved